Struggling to convince customers of PPF’s value? Their doubt costs you sales. A SELF RESTORING DEMO device provides the visual proof you need to close deals confidently.

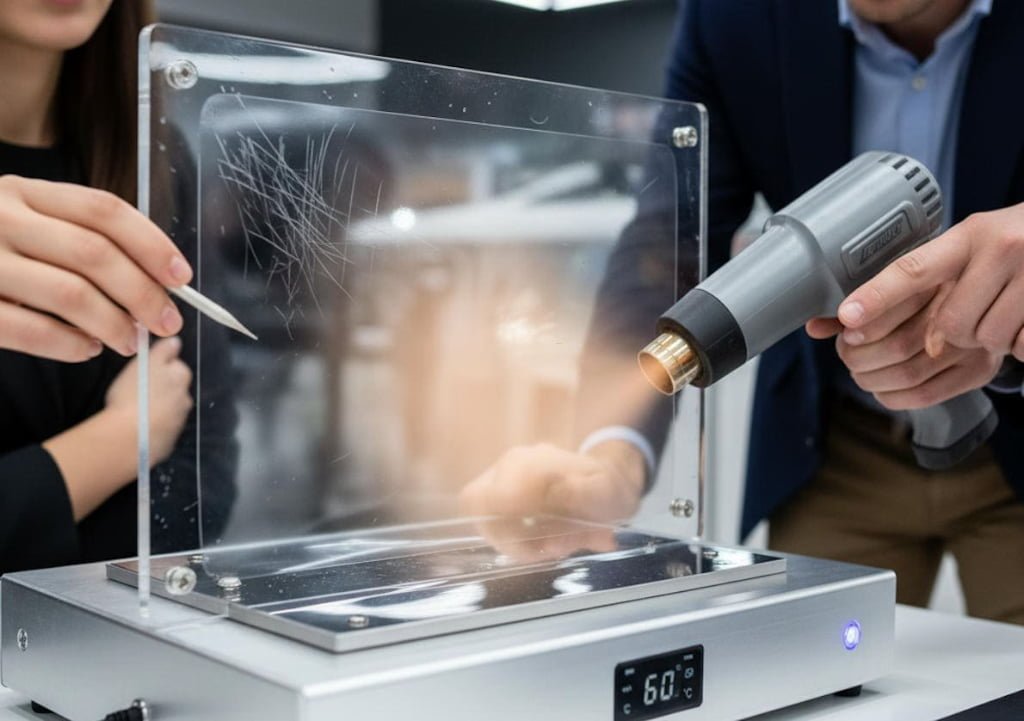

A SELF RESTORING DEMO device helps you show clients how Paint Protection Film heals. You scratch a piece of film on the device, then apply heat. Customers see the scratches disappear instantly, proving the quality and justifying the investment.

For over a decade, my team and I have lived and breathed PPF. I remember the early days. We would spend ages trying to explain the benefits of a high-quality film. We used words like “elastomeric polymers” and “top-coat technology.” Most of the time, I just saw blank stares. Customers want to see, not just hear. They want proof. That’s why demonstrating the film’s properties is so important. It turns a technical lecture into a “wow” moment. It’s the difference between a confused customer walking away and an excited customer ready to protect their car. Let’s explore how you can create that “wow” moment every single time.

What is self-healing PPF, really?

Explaining “self-healing” can sound like science fiction to your customers. This confusion can make them think it’s just a marketing gimmick. Let’s break it down into simple terms.

Self-healing PPF is a clear, protective film for a car’s paint. It has a special top layer that can repair itself from minor scratches or swirl marks. When you apply a little heat, the material returns to its original smooth state.

The Layers Behind the Shield

I once had a customer who was on the fence about getting PPF for his brand-new sports car. A week later, he came back with a long, shallow scratch on his door from a shopping cart. He was devastated. That’s when the real value of PPF clicked for him. Self-healing PPF is like having a regenerating shield for your car’s paint. It is made of several layers, but the magic happens in the top layer. This top coat is usually made from an elastomeric polymer. Think of it like memory foam. When you press on memory foam, it leaves an indent. But it slowly returns to its original shape. Self-healing PPF works in a similar way, but it reacts to heat. The polymers are designed to hold a specific structure. When a light scratch breaks that structure, a little heat gives the polymers the energy they need to rearrange and flow back into their original smooth, interlocked state. This makes the scratch literally disappear.

| Feature | Standard Vinyl Film | Self-Healing PPF |

|---|---|---|

| Main Purpose | Color change, aesthetics | Impact and scratch protection |

| Top Layer | Simple protective laminate | Elastomeric polymer top coat |

| Scratch Response | Scratches are permanent | Scratches disappear with heat |

| Thickness | 2-4 mils (thinner) | 6-10 mils (thicker, more durable) |

| Lifespan | 3-5 years | 7-10+ years |

How does self-healing PPF actually work?

“It heals with heat” sounds too simple, and skeptical customers need more. You need a clear explanation to justify the premium price. Let’s explore the process in an easy way.

The science is based on a concept from chemistry called thermoplastic polyurethane (TPU). The film’s top coat has a molecular structure that, when scratched, can be reset with energy. This energy is usually heat from the sun, a heat gun, or hot water.

The Healing Process Explained

Think of the PPF’s surface as a net made of strong, flexible ropes tied together. When a light scratch happens, like from a tree branch or a key, it pushes these ropes apart. It doesn’t actually cut them. The “net” is just temporarily deformed. The scratch you see is the light catching on the edges of that deformed area. Now, what does heat do? Heat adds energy. This energy makes the flexible “ropes” (the polymers) vibrate and move more freely. As they move, the natural tension in the net pulls them back to their original, tightly woven positions. The deformation is gone, and the surface becomes perfectly smooth again. Because there are no more rough edges to catch the light, the scratch becomes invisible. It’s not magic, it’s just very clever material science. I find that when I explain it this way, customers get it. They understand they are paying for advanced technology, not just a simple piece of plastic. This understanding builds trust and makes the sale much easier.

What is a SELF RESTORING DEMO device?

Telling a customer that PPF heals is one thing. Watching them lose interest as you try to explain it is another. A SELF RESTORING DEMO device solves this communication gap.

This device is a small, portable tool specifically made to demonstrate the self-healing ability of PPF. It usually has a heated surface and a holder for a small, pre-scratched piece of film. It shows the healing process live in seconds.

Turning Doubters into Believers

In our shop, we have a SELF RESTORING DEMO device from our own brand, Keyinstools, right on the front counter. It’s probably the best salesperson we have. When a customer asks about PPF, we don’t start with a long speech. We just say, “Let me show you something.” We take a small sample of our premium PPF and scratch it with a wire brush right in front of them. You can see their expression change—they think we’ve just ruined it. Then, we place the scratched film onto the heated block of the demo device. Within five to ten seconds, every single scratch completely vanishes. The film looks brand new again. The customer’s skeptical look turns into amazement. At that moment, the value of self-healing PPF becomes real. They are no longer just hearing about a feature; they are witnessing it. This powerful, visual proof instantly answers their questions about durability and quality. It also allows us to compare different film qualities side-by-side, proving why a premium film is worth the investment. It’s an essential tool for any serious installer.

Conclusion

The SELF RESTORING DEMO device transforms abstract features into tangible proof. It helps you build trust, demonstrate value instantly, and turn skeptical shoppers into confident buyers with a simple demonstration.